Seamless

plastic cellar #1

Benefits

Seamless, sealed

Seamless cellar is manufactured using a special technology – the method of rotational molding. Due to this, the product does not have welding seams. The cellar is a one-piece construction and has absolute leakproofness.Durable food grade plastic

We use durable and safe for the environment and human health food grade polyethylene (LLDPE) in the production process of seamless cellar. The material has increased durability, hardness and impact resistance. Mold and fungus do not live on it and do not multiply.The service life is more than 100 years

Highly durable food grade polyethylene and manufacturing technology makes the seamless cellar almost eternal, which will serve you and your grandchildren.Comfortable temperature for food storage

Seamless cellar is equipped with natural-type supply and exhaust ventilation. A well-thought-out system allows you to maintain the necessary humidity level and a comfortable temperature indoors all year round.It is not subject to corrosion and external factors

The plastic cellar of seamless cellar does not form dampness and mold, it does not rot and does not rust. Seamless cellar is equipped with a built-in metal frame made of 13Mn6 steel DIN 17145 (09G2S GOST 19281-2014), which is 50% stronger than ordinary steel. This ensures the durability of the cellar, and allows it to withstand the pressure of heavy soils, as well as high groundwater.Comparison of the cellars

Seamless plastic cellar

Welded cellar

Concrete cellar

What’s included

-

Floor and shelves

-

Ladder and metal frame

-

Weather station and lighting lamp

-

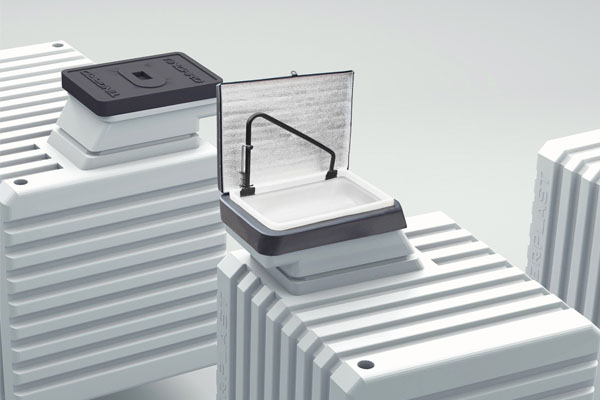

Hatch cover and handrail

-

Supply and exhaust ventilation

-

Mini Cargo Lift

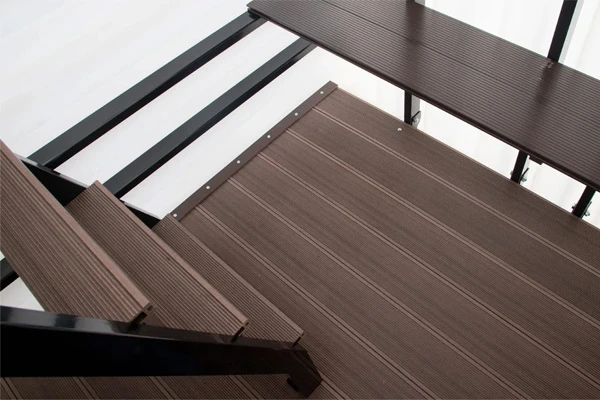

Floor and shelves

The standard equipment of cellar includes a wooden floor and comfortable wooden shelves located around the perimeter of the cellar on three levels. The floor and the shelf system are made of dry coniferous wood, additionally treated with a special antiseptic to give an aesthetic appearance, as well as protection from the formation of fungus and mold.

The width of the shelves is 300 mm, which is optimal. On such shelves it is convenient to store three-liter cans in two rows and boxes with vegetables.

Depending on the model of the cellar, the shelves allow you to place:

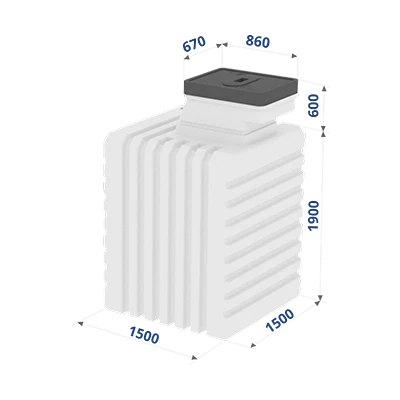

Cellar 1500 – 102 cans, 8 boxes

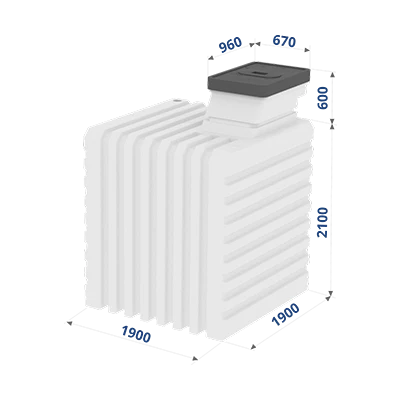

Cellar 2000 – 203 cans, 20 boxes

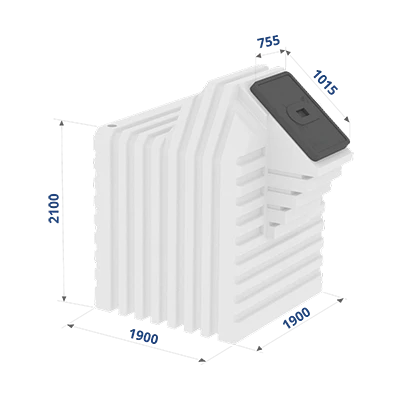

Cellar 2000B – 203 cans, 20 boxes

Cellar 2500 – 251 cans, 25 boxes

Cellar 2500B – 250 cans, 25 boxes

Cellar 3000 – 300 cans, 30 boxes

Cellar 3500 – 350 cans, 35 boxes

Mini Cargo Lift

- Load capacity 150 kg

- Two colors — black and yellow

- Anti-slip strips

- Made of galvanized metal

- Covered with powder paint

Product line

Characteristics of cellars

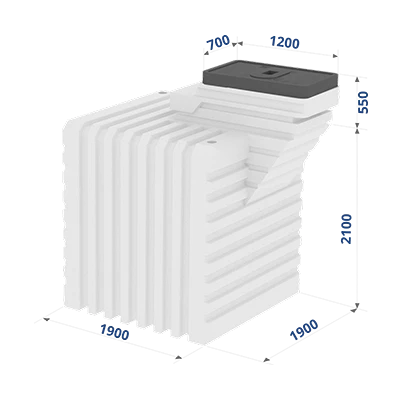

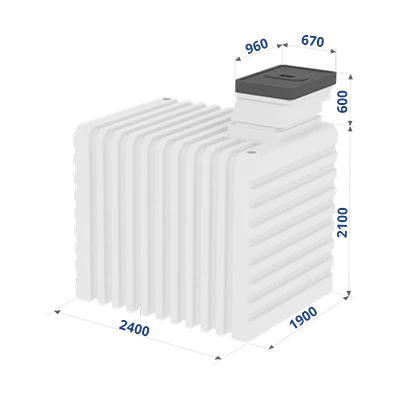

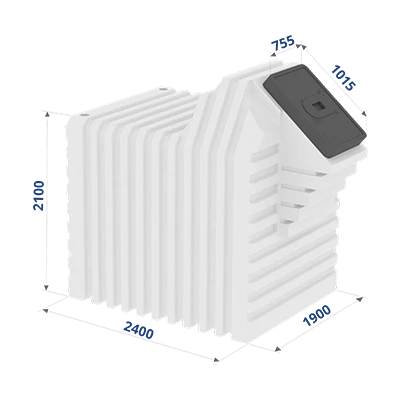

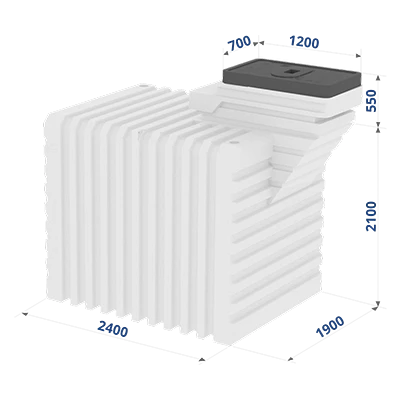

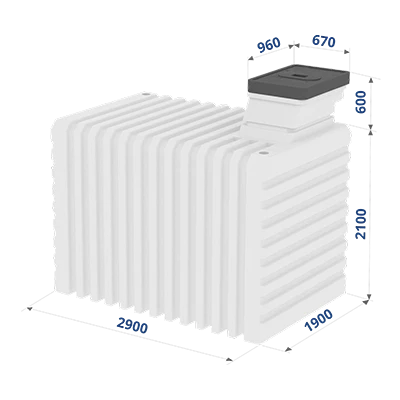

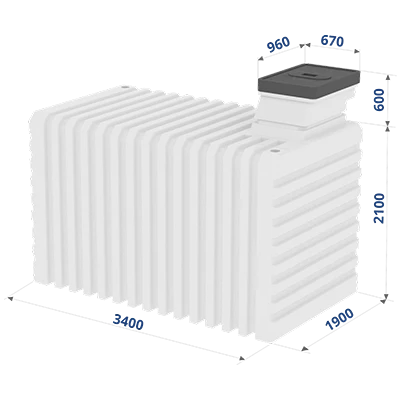

| 1500 | 2000 | 2500 | 3000 | 3500 | 2000B | 2000K | 2500B | 2500K | |

|---|---|---|---|---|---|---|---|---|---|

| Dimensions l/w/h, cm | 150/150/250 | 190/190/270 | 240/190/270 | 290/190/270 | 340/190/270 | 250/190/270 | 250/190/265 | 300/190/270 | 305/190/265 |

| Entrance, cm | 86/67/60 | 96/67/60 | 96/67/60 | 96/67/60 | 96/67/60 | 101.5/75.5/87.5 | 120/70/600 | 101.5/75.5/87.5 | 120/70/60 |

| Wall thickness | up to 15 mm | up to 15 mm | |||||||

| Weight, kg | 410 | 600 | 680 | 800 | 900 | 630 | 650 | 710 | 760 |

| Leakproofness | 100% | 100% | |||||||

| Material | Food grade polyethylene | Food grade polyethylene | |||||||

| The service life | is more than 100 years | is more than 100 years | |||||||

What’s included

- Metal frame

- Metal ladder

- Manhole cover

- Wooden flooring

- Collar for the cellar neck

- Exhaust ventilation

- Supply ventilation

- Weather station

- Built-in LED lighting

- Wooden shelves